Adding a T-connection

Incorporating a T-connection in your building project is an important architectural and structural feature. While most block companies manufacture their own T-Forms, builders find an advantage in “site cutting” a T-connection rather than using the pre-manufactured forms. Site cutting T-connections can reduce the number of vertical stack joints and requires less time than assembling T-Forms.

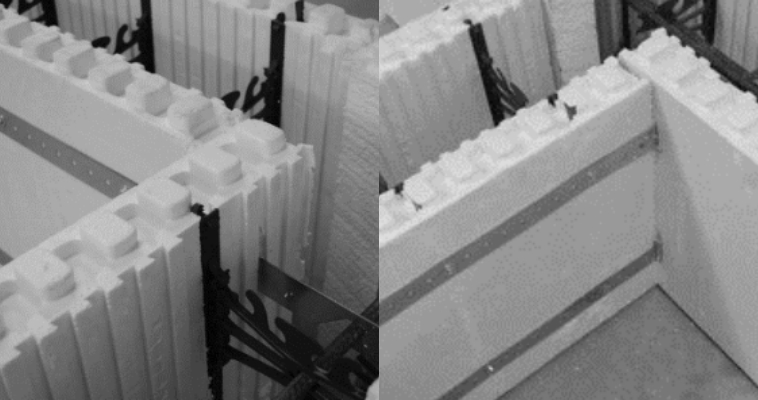

T-Form Support Straps were created to aid in installation and support of site cut T-connections. The steel straps are designed to hook over the internal reinforcing bar on the main wall of the T intersection and be secured to the external webs of the perpendicular portion of the wall.

Using T-Form Support Straps reduces the amount of wood strapping and eliminates unnecessary labour as the straps do not need to be removed post-pour.

Installing 2 straps on both sides of the first course; 2 on the lower web connection and 2 on the upper web connection. Additional courses are assembled in the same manner.

T-Form Support Straps are 24” long x 1-1/2” high (610mm x 38mm), Grade A 16ga steel.

Instructions

STEP 1

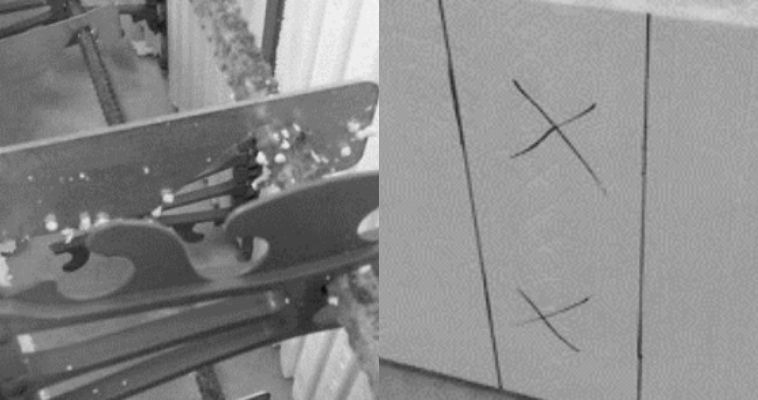

Mark required location of T-Connection on the main wall. Only cut out foam equal to the size of the block core, NOT the entire block width.

STEP 2

Remove the foam at the connection and cut off webs on the side closest to the “T”. Cut lengths of rebar long enough to span the cut section and lock into both solid webs (not the rebar grooves) located on either side of the T-connection.

STEP 3

Push the hook end of the T-Form Support Strap through foam and hook onto the support pieces of rebar. A small cut with a keyhole saw may make installation easier.

STEP 4

Screw the T-Form Support Strap to the web on the outside of the block with 2” (51mm) screws or equivalent. Gaps can be filled with low expansion foam, as required.

STEP 5

Install reinforcing steel as per Code, or as per Engineer/ Architect specifications.

STEP 6

Repeat steps 1-5 for each consecutive row.

NOTE: While the T-Form Support Strap provides convenient support for T-Wall construction, caution must be taken while pouring concrete due to increased risk of concrete pressure. Ensure placement and vibration techniques are followed closely.